How to raise a Meat Bird in 9 weeks

We had had our turkeys Big Man and Little Girl (previously known as Christmas and Thanksgiving) for two months, give or take when we began talking it over some. Should we take on the challenge of raising even more protein on our property? The turkeys were not too difficult yet, feed and water twice a day, let them follow us around the yard, shoo them away from the growing garlic (I don’t know why they loved the garlic but I hope it makes them tasty later around the holidays) and more or less let them have a stress free life which would ultimately mean from what we understood, a tastier finished product. Should we, perhaps try our hand at raising meat birds?

On July 1st we just happened to call Alaska Feed Company located in Fairbanks because I remarked during breakfast that I noticed they were advertising that they had a few meat birds left. On the call, they advised us they had a total of four birds left. The staff at Alaska feed advised that they did not expect two of them to survive. If we bought the other two healthy birds they would give us the other two, free of charge. Could we do it? Could we take the challenge of raising our own meat birds?

Challenge Accepted

Always willing to accept a challenge my husband and I nodded to each other, quickly cleaned up from breakfast, and headed to town to check out these little chicks. We knew we had the makeshift brooder boxes, we had pine shavings thanks to the layer hens so we would only need to purchase the chicks and some feed. In our opinion, raising a small amount of meat birds was the perfect trial run for us. The type of chickens that Alaska Feed had available were Cornish Cross broilers. These types of chickens have all white feathers and red combs.

The Cornish cross chicken is a mix between a Cornish Chicken and a White Rock Chicken. They are very fast-growing and on average are ready for harvest within eight weeks they are usually ready for harvest. There is only one purpose for these types of birds. They can be harvested within 6-7 weeks because of their fast weight gain. Unlike our laying hens that like to roost due to the increased safety, Cornish Cross broilers typically do not roost but instead are content with sitting on the ground. They are very calm, docile birds which make handling them very easy.

Chickens in the Garage, yet again

Once again our garage was full of chirps. We had just evicted the last poultry in the garage. Here we were again, with a garage full of chicks a chirping. While it might sound as if I am frustrated by it, it was amusing to hear the chicks non stop when I walked through the garage. We all would stop by and say “hello”. We kept a solid watch on the two sickly or infirm ones.

Over time we nicknamed the chicken with her bum feathers all pecked off as “sore bum” and the one with the oddly mishappen leg “gimpy”. Over the weeks we steadily fed them their diet of game bird crumbles and water and by about the second week their full feathers had grown in which would then allow us to place them outside where we could harden them off. By this point, I was more than grateful since chicks are cute but after a while, they do start to smell a lot. By the end of July, it became apparent that three of the four would survive.

Tough decisions

It was becoming apparent that while “sore bum” would survive, “Gimpy” would most likely not. The other chickens were now well on their way to their harvest size. Gimpy had stayed almost the same size as what he was when we first got him. Due to his malformed leg, he could not walk. He was not digesting food at all as his crop was visibly impacted. Ultimately this was a bird that would most likely never get any larger. We found that the yellow jackets in the area were stinging it mercilessly on its rear. We decided to cull poor Gimpy. He would never survive such attacks from nature. I could only imagine the pain the poor little guy must have been experiencing with all the yellow jackets in the area.

Harvest day

I have a pair of brown jeans that now only come out when typically one thing is happening; livestock harvest day. I add the layers of clothing on these days like a surgeon washes his or her hands before the surgery. There is an almost meditative type of thought process going as I think over what is about to be done. What needs to be placed where? Hot water for cleaning hands? Check. Recently sharpened knives? Check. Is fresh water available for washing off the animal? Check. Ice cold brine water in cooler for placement of now harvested animal in place? Check.

We decided pretty early on that we would not harvest both the turkeys and chickens on the same day. While it would make sense to process all the poultry together we knew we would need at least half a day for the turkeys alone. We decided this early on and for that I’m grateful. It gave us time to figure out what went right and wrong during the harvest of the turkeys.

Lessons learned with the turkeys

During our harvest with the turkeys we learned that first, I did not cut deeply enough at Big Man’s neck. While he was upside down which calmed him, he did take a while to bleed out. Not good. Next, plucking feathers went like a breeze with both turkeys so we knew what to do right there. 140 degrees was the perfect temperature to soften up those feathers and I used a dash of H20@Home dish soap. I had heard earlier to add a small amount of soap which helped with the plucking. I had one knife available for the neck cut, one for around the rear, and my favorite filleting knife that I use on rabbits because it’s long, sharp, and flexible. Bowls were available for offal. I always use the liver, heart, neck, and feet in stuffings or soups.

While the turkeys took a good portion of the day, the chickens took us about 15-20 minutes to process for each bird. The last bird being the easiest as now I had this down pat. I jokingly told Edward as my hand was deep inside the warm cavity of the chicken that just thirty minutes ago was alive that I could do chickens all day if they were all this easy. In fact, they were almost easier than rabbits. Almost. We started working with the chickens by 10:00 am. By lunchtime, I was washing my hands and preparing to get to our next job on the homestead. We needed to apply the final coat of paint on the deck. Nice.

Economics of raising meat birds

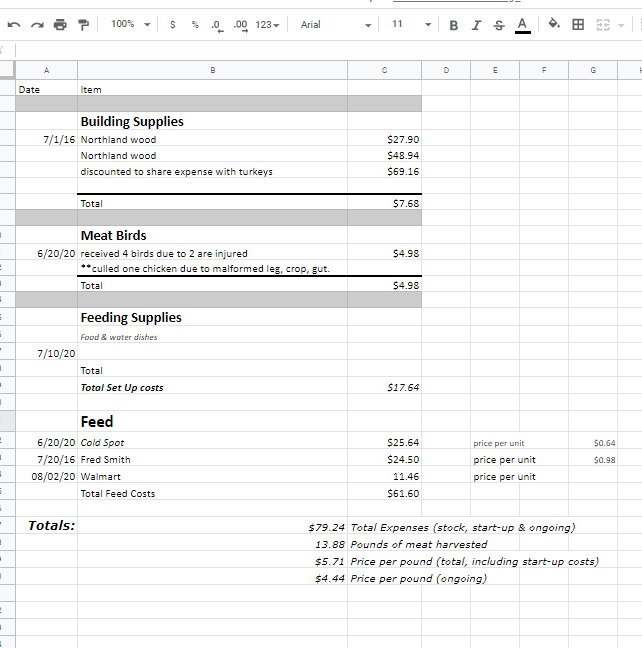

So like I broke down raising the turkeys, I used the same type of spreadsheet for raising the meat birds. Just how expensive were these homegrown chickens? Now I admit, I received two birds for free so I had an advantage. Regardless though what was the breakdown of cost? The Safeway nearest to me here in North Pole has Foster Farms Fresh & Natural Whole chicken available for $1.49 a pound. Their organic chickens go for a bit more at $2.99 a pound as of today, 24 August. Technically I cannot compete against Organic. Just like I mentioned with our turkeys that our birds will never get that USDA seal of approval.

My cost ended up a bit higher at $5.71 a pound with start-up costs included. The price per pound just based on feed was $4.44. I know as we become a bit more adept at this process this will go down. We do intend to purchase many more meat birds next year as Alaska Feed gives discounts if you purchase your meat birds in bulk. This means it is very possible both due to our increased knowledge of growing poultry as well as rising food prices that our cost will be lower than store prices. Another win in my book.

With this knowledge it becomes apparent that we will be able to raise or grow much of our food on our 1.7 acre homestead. With that we become more self reliant.

Thank you for the cost breakdown, it was very helpful.